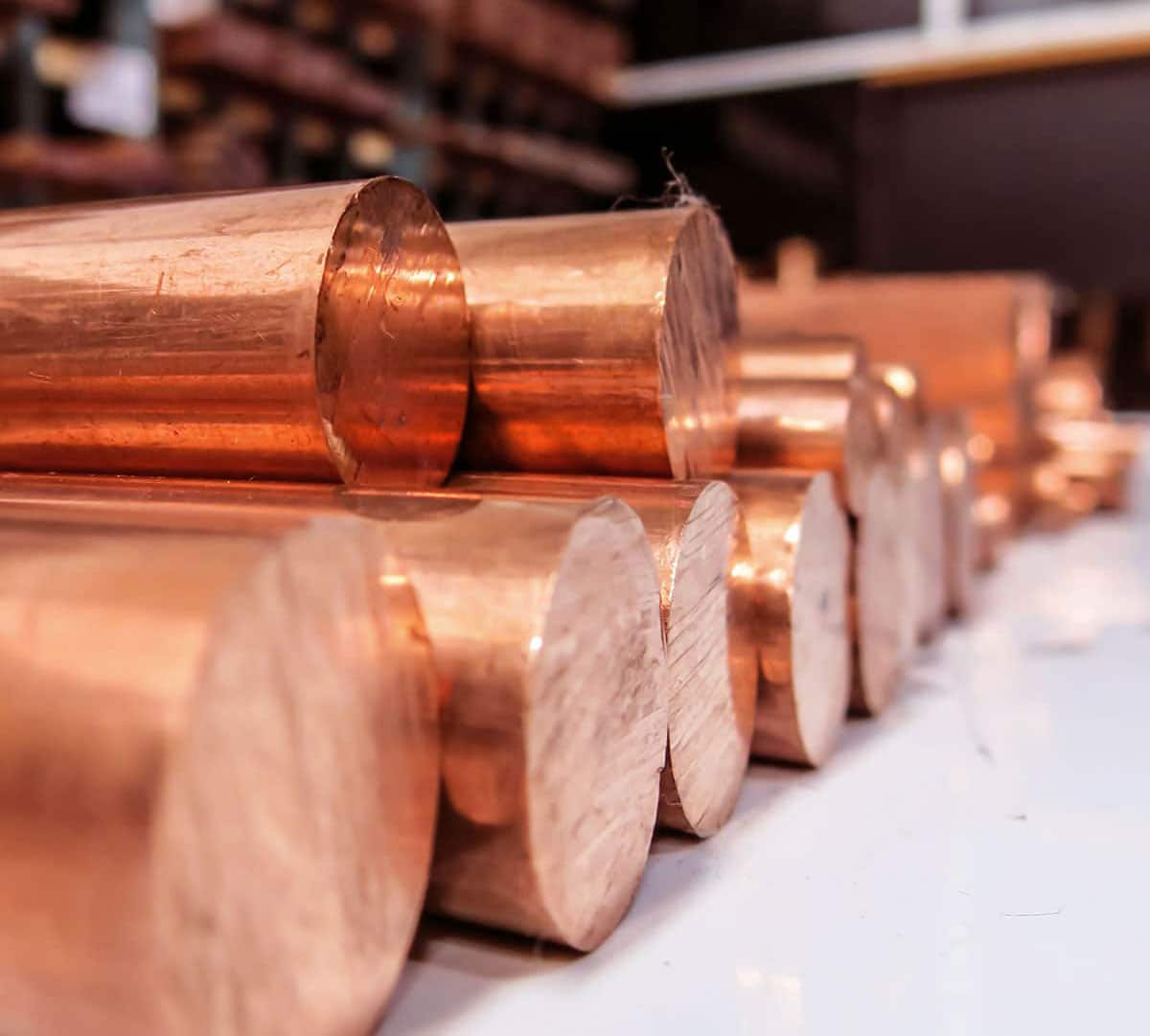

The Importance of Top Quality in the Manufacturing of Copper Products

The relevance of high quality in the production of copper products extends much past simple conformity; it is indispensable to enhancing performance throughout different industries. High-grade copper not only enhances conductivity however also assures resilience and reliability, which are important in applications varying from electronic devices to automotive systems. The effects of poor production practices can resound via prices and security requirements, eventually affecting consumer depend on. As we discover the diverse nature of quality, the concern arises: just how can suppliers balance these challenges to accomplish excellence?

Effect On Product Efficiency

The high quality of copper products plays an essential function in identifying their total performance in various applications. High-quality copper exhibits remarkable electric conductivity, thermal conductivity, and deterioration resistance, which are vital attributes for sectors such as electronic devices, building and construction, and automobile.

Moreover, the mechanical residential or commercial properties of copper, consisting of ductility and tensile stamina, considerably affect its efficiency in making procedures. Copper items that meet stringent high quality standards can endure considerable stress without deforming, consequently enhancing toughness and decreasing the chance of failure popular environments.

In addition, the surface area coating of copper items effects their efficiency. A smooth, well-treated surface area can protect against oxidation and various other kinds of destruction, eventually lengthening the life of the part. In recap, the high quality of copper products directly impacts their performance, dependability, and longevity across various fields, making it necessary for manufacturers to stick to strenuous top quality control steps throughout the manufacturing procedure.

Expense Implications of Poor Quality

Purchasing top quality copper items is essential, as the cost effects mediocre can be considerable for producers and end-users alike. Poor high quality copper can cause boosted failing rates, leading to expensive fixings and replacements. Manufacturers may deal with substantial downtime as defective items require remembers or rework, interfering with manufacturing routines and influencing total effectiveness.

From an end-user viewpoint, the implications are just as extreme. Poor-quality copper can lead to inefficiencies and enhanced functional prices, as devices might require even more constant maintenance. Ultimately, the initial financial savings acquired from picking lower-quality copper products can be overshadowed by these lasting prices, making the quest of high quality not simply an issue of performance, yet a crucial economic factor to consider in the production industry.

Security and Compliance Standards

Making certain security and compliance requirements in the manufacturing of copper items is vital to keeping operational integrity and safeguarding both workers and consumers. The production process need to abide by rigid policies stated by companies such as the Occupational Safety And Security and Wellness Administration (OSHA) and the Environmental Security Agency (EPA) These regulations outline vital safety techniques, including correct handling of basic materials and waste monitoring, making certain a safe work atmosphere.

Furthermore, compliance with sector criteria such as ASTM International and ISO accreditation is important. These organizations give standards that assist manufacturers execute best techniques in high quality control and safety and security procedures. Routine audits and assessments should be carried out to guarantee adherence to these requirements, as non-compliance can cause harmful conditions his comment is here and possible lawful implications.

Client Trust Fund and Fulfillment

Depend on and fulfillment among customers play a pivotal function in the success of copper product producers (Copper Products). High-quality copper products not only satisfy rigorous sector criteria however additionally meet client assumptions, promoting loyalty and repeat organization. When consumers are positive in the top quality of the items they purchase, they are most likely to create a long-lasting relationship with the manufacturer, which can bring about recommendations and favorable word-of-mouth

To construct this trust fund, suppliers need to prioritize high quality control throughout the manufacturing process, making certain that each copper item fulfills or exceeds requirements. Openness in manufacturing methods, coupled with commitment to consumer solution, reinforces the assumption of dependability. Furthermore, timely distribution and responsiveness to consumer inquiries significantly boost complete satisfaction degrees.

Consumer comments need to be proactively looked for and incorporated right into item advancement cycles to continually improve offerings. Involving customers in dialogue concerning their requirements and choices cultivates a sense of collaboration, more strengthening their trust fund in the supplier. Ultimately, a reputation for top quality and customer-centric techniques identifies effective copper item makers in an open market, preparing for sustaining client connections.

Lasting Company Success

A producer's commitment to high quality is essential to achieving long-term service success in the affordable copper products market. High-grade items foster client loyalty, making certain repeat service and positive references that drive development. In a market where integrity and efficiency are paramount, business that prioritize high quality over cost-cutting measures are most likely to attract attention.

Furthermore, consistent high quality minimizes the incident of issues and rework, bring about lower operational prices and enhanced performance. This streamlined production procedure makes it possible for makers to assign sources efficiently, enabling for investments in innovation and innovation. Organizations that adjust to spend and market changes in quality enhancements are much better placed to satisfy evolving customer demands.

In addition, keeping stringent high quality standards enhances a business's online reputation, bring in new clients and Read Full Report potential collaborations. A robust track record for top quality can work as a differentiator in crowded markets, opening up doors to lucrative agreements and cooperations.

Ultimately, a steadfast dedication to high quality not just makes sure compliance with market laws yet additionally grows a lasting company design. By installing top quality right into every element of the manufacturing process, companies can protect their place as leaders in the copper products industry, leading the way for sustaining success.

Verdict

Finally, the importance of high quality in copper product production is extremely important. High-grade materials improve efficiency, decrease costs connected with failings, and make certain conformity with security criteria. Moreover, prioritizing top quality grows consumer trust fund and satisfaction, which are necessary for maintaining long-term business success. As markets increasingly rely on copper for vital applications, keeping rigorous quality assurance is important to safeguard an affordable advantage and maintain a credible market visibility.

The value of high quality in the manufacturing of copper products expands far beyond simple conformity; it is indispensable to optimizing efficiency throughout numerous industries. In summary, the top quality of copper items directly influences their capability, integrity, and longevity throughout numerous markets, making it important for producers to stick to strenuous high quality control steps throughout the production procedure.

A producer's commitment to high quality is indispensable to achieving long-lasting service success in the competitive copper products market.

Comments on “Why Copper Products Are Important for Electrical Applications and Reliable Circuitry”